An alternative to the linear adjustment with Bansbach gas springs are our hydraulic systems.

Micro-Hydraulic

With the new micro-hydraulic cylinders, high forces can be realized in a compact construction. With the standard piston diameters from 13 – 24mm and a maximum pressure of 200 bar, forces up to 9,000N can be achieved. The stroke will be individually adjusted according to the customer’s requirements.

By using numerous components of the gas spring manufacturer, high flexibility and short delivery times are available

Hydraulic Pumps

With the new Bansbach hydraulic pump, the height of a great variety of applications can be adjusted by simply pumping. The pump can be completely operated without external energy supply. The movement is effected by simply pumping. Due to the weight of the application, the reset is always controlled and can be effected by opening the valve with a movement at the lever.

We offer here also a very flexible product range which will be adapted to the characteristics of your application and therefore optimally fulfills your requirements. Please contact us!

Product Characteristics Hydraulicpump HP

- Maintenance-free

- Completely independent of external energy supply

- Extension forces up to 10 kN

- Strokes from 80 - 400 mm possible

- Different connecting parts available

- Operating temperature: + 10°C - + 40°C

- Lowering speed customised

- Overload protection

The Bansbach easymotion

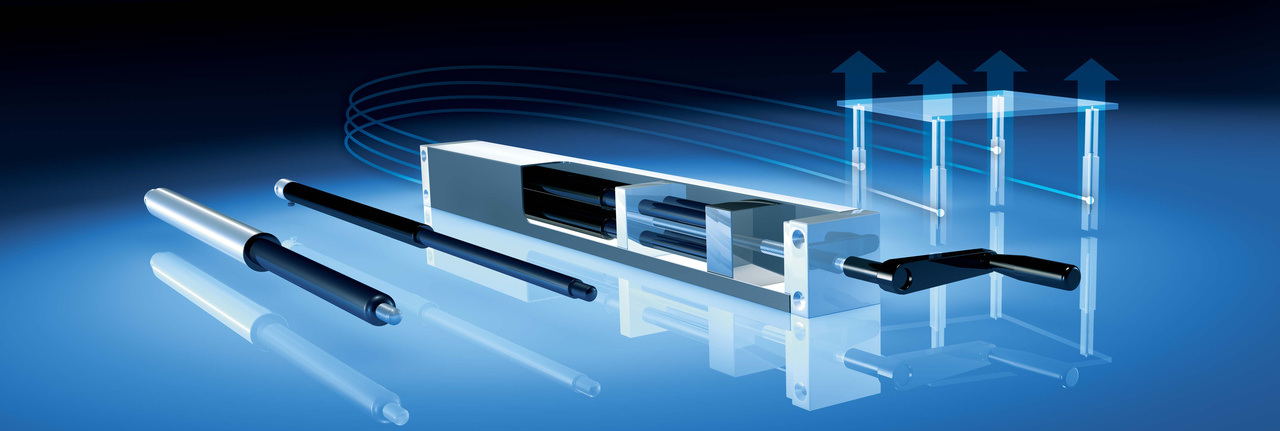

An alternative to the linear adjustment with Bansbach gas springs is our linear hydraulic actuation system. Our easymotion® system can control multiple adjustment cylinders synchronously, which is achieved by simultaneously controlling each cylinder. Whether light or heavy, this system can be fitted on any application and can be customized to fit your individual needs, including multiples per application (i.e. legs on table). Numerous Bansbach gas spring components are used in the production of the easymotion® system, maintaining our high quality standard.

Our main applications you can see in the next table:

Office workplace

Office workplace- Work Benches

- Assembly Tables

- Lecterns

- Sales Counters

- Mobile Workshops

Hospital Beds

Hospital Beds- Massage Tables

- Laboratory Furniture

- Bathtubs

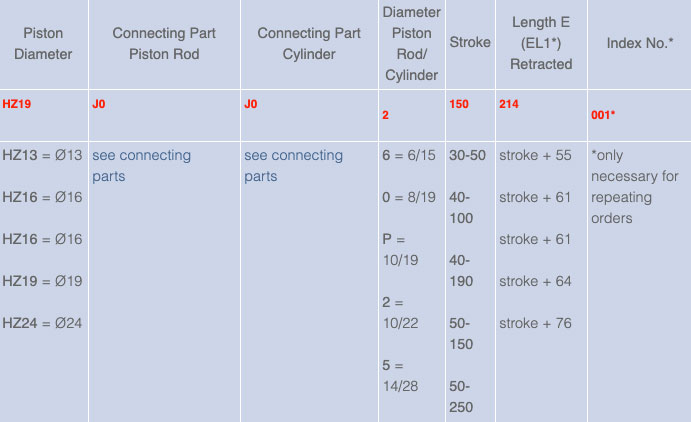

There are different kinds of Cylinders. By accessing components from the Bansbach gas spring production, a large variety of cylinders can be offered. The E-Cylinder alone is not designed to absorb side forces and also requires an additional guide. A large assortment of A-Cylinder variations is available out of the gas spring production, guaranteeing our high quality components.

The A-Cylinders do not require further guiding and can be mounted directly onto moveable parts of the application. Gas spring components as well as our gas spring technology are used for this cylinder adjustment variation. The Z-Cylinder is a combination of our hydraulic adjustment cylinder and a gas traction spring. This variation allows the system to be compressed without the need of an external compression force (load). The Z-Cylinder can be installed in any position. For all our Cylinders you can order different connecting parts for piston rod and various connecting parts for cylinder.

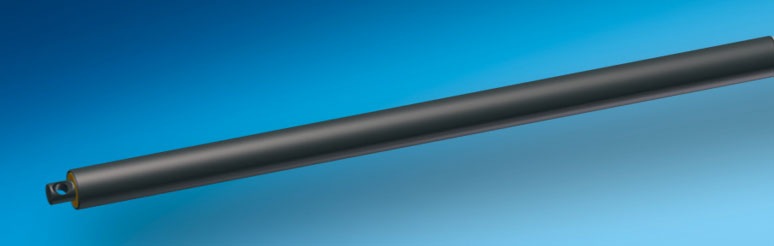

E-Cylinders

E-Cylinders- Max. Weight 900kg per system

- Stroke Length: 150mm-400mm (special strokes from 30mm up to 600mm)

- Several Connecting parts

- Force per E-Cylinder required to compress: 70N

- Special E-Cylinder designs available upon request

more informations

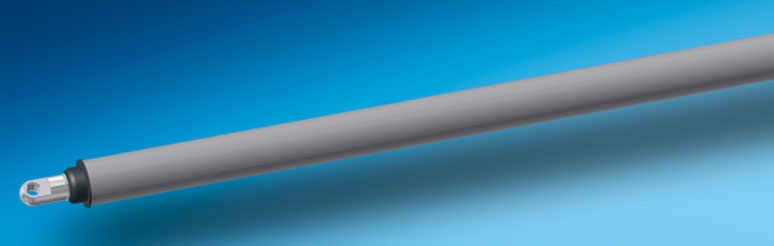

more informations A-Cylinders

A-Cylinders- Max. Weight 600kg per system

- Stroke Length: 150mm - 400mm (special strokes from 30mm up to 600mm)

- Force per A-Cylinder required to compress: 70N

- Several Connecting parts

- Special A-Cylinder designs available upon request

more informations

more informations Z-Cylinders

Z-Cylinders- No external compression force (load) required

- Max. Weight 600kg per system

- Stroke Length: 150mm - 400mm (special strokes from 30mm up to 800mm)

- Standard Compression Force: 100N (approx 10kg)

Attention: The max load per cylinder will be reduced accordingly. Other compression forces on request. - Several Connecting parts

more informations

more informations

Also the next four features are really important in die easymotion system. The new Bansbach linear unit can be mounted or installed at your application without any big efforts. With the linear unit, you will get a complete system with installed adjustment cylinder. The pumps for operating easymotin® cylinders synchronously.

The Actuation will be your choice: comfortable adjustment by electric motor or adjustment 100% independent of electricity. Our easymotion® systems can be operated using either a manual crank or an electric motor (230V or 110V). An adjustment speed of up to 44mm/sec can be reached, depending on the load and the corresponding electric motor.

Due to its modular construction, the Bansbach Guide Column is extremely flexible and can be used in numerous applications without regard to the number of columns needed. Nearly all requirements can be met with the variable lengths of the traverse members offered. The piston rod, which is secured against possible rotation, offers additional security.

- Stroke from 150 to 400 mm

- E-Cylinder model 1 and 2 and

Z-Cylinder model 2, Ø 8/19 suitable - Different adapter plates for fixing

- Stroke loads of up to 150 kg / Cylinder

- Anodized aluminium

- Force required to compress: 100N

- Pumps for operating 1-6 cylinders

- Max. weight: 900kg per system (model 4)

- Made of anodized aluminum

- Operation by crank or electric motor

- Mounting in any position is possible

It’s your choice: comfortable adjustment by electric motor or adjustment 100% independent of electricity. Our easymotion® systems can be operated using either a manual crank or an electric motor (230V or 110V). An adjustment speed of up to 44mm/sec can be reached, depending on the load and the corresponding electric motor.

- Rotating-Secured

- Available in any length (Note: please consider the minimum length in relation to the stroke length)

- Hose connection possible on both sides

- Suitable for all adjustment cylinders

- force required to compress: 100N

The accessories...

very simple assembly

very simple assembly- pump and cylinder will be delivered ready for use

- no filling, no ventilation

- plug in and get started

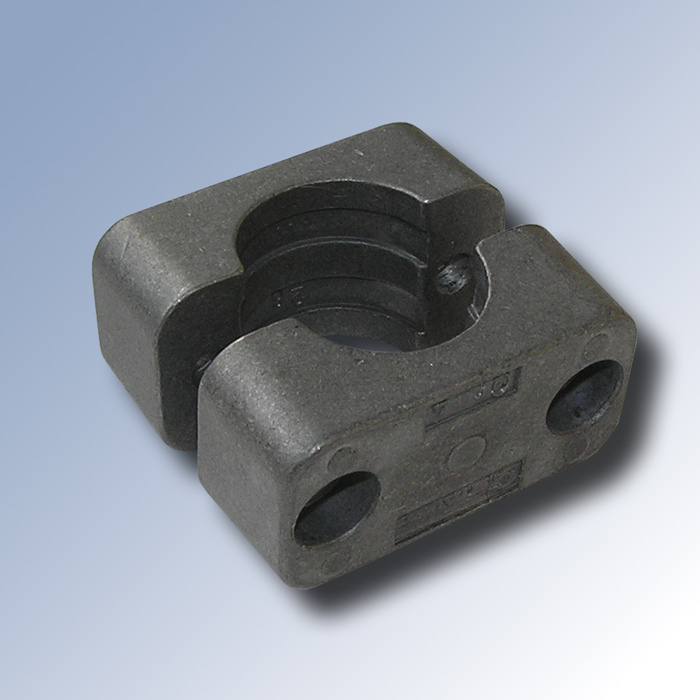

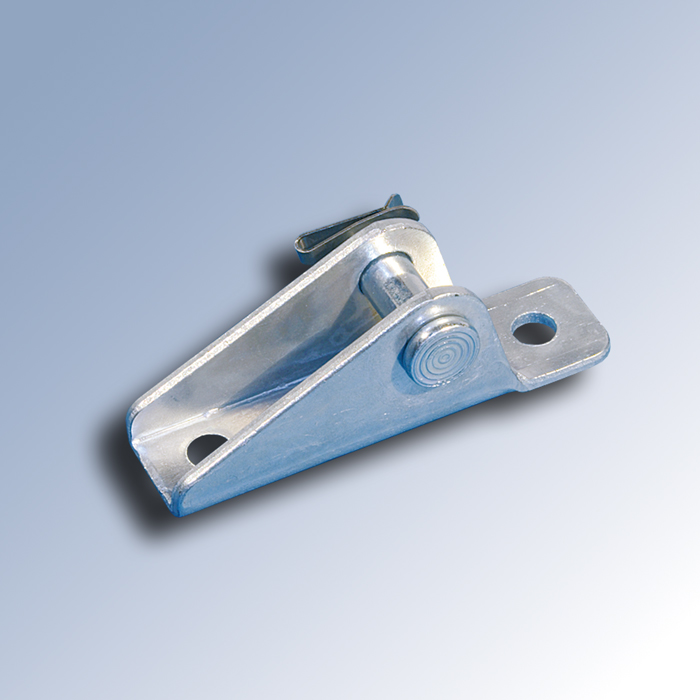

Prevents the uncontrolled running in of the cylinders at damage or disruption of the tubes

Prevents the uncontrolled running in of the cylinders at damage or disruption of the tubes- Available as an option for all easymotion systems (standard at 900kg)

Order number: EM-AC-BS1

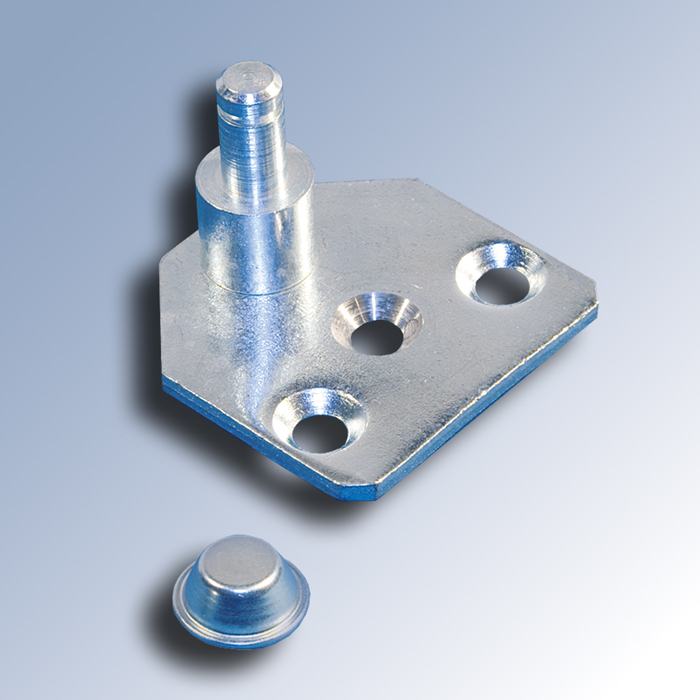

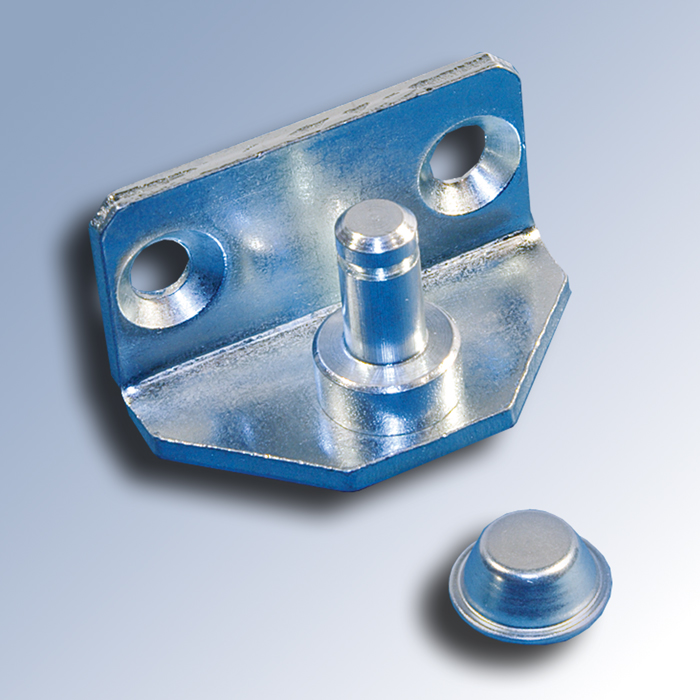

- Bracket to mount the A-Cylinder on the application

- Distance between the boreholes: 40 mm

- 2 clamps per A-Cylinder recommended

Order number: EM-AC-FU2

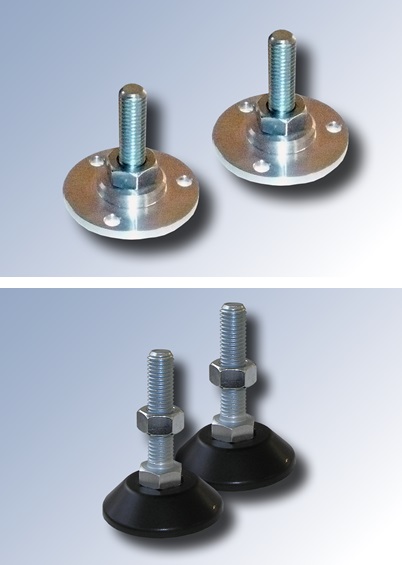

- Foot of aluminum

- Height adjustment possible

Order number: EM-AC-FU3

- Foot of plastic

- Height adjustment possible

Order Number: EM-AC-KIT

Order Number: EM-AC-KIT

- 250 ml Bansbach hydraulic-oil

- Refill syringe for easymotion

- lock nuts, clamp rings, tube bushing, tube cutter

Order number: EM-AC-SC1

- Diameter 4 mm

- Max length per cylinder 5 m

- Ratio between the single tubes max 5:1

- Min bending radius 50 mm

- If stroke <100 mm: max tube length 1500mm

- also available in filled and weld-shut condition (max 1500 mm

Fitting connecting parts: AB/ZB and AW/ZW

Fitting connecting parts: AB/ZB and AW/ZW- Max force: 250kg

Fitting connecting parts: AB/ZB and AW/ZW

Fitting connecting parts: AB/ZB and AW/ZW- Max force: 250kg

Fitting connecting parts: AB/ZB and AW/ZW

Fitting connecting parts: AB/ZB and AW/ZW- Max force: 600kg

Dining Tables

Dining Tables