The Bansbach® easylift gas spring system offers you the greatest possible flexibility: Gas springs in every size, force and implementation.

This is possible:

Force: 7-12.000N

Stroke: 10-1000mm

Diameter/Cylinder piston rod: 3/8-30/70

Model: Standard, with scraper, with convertube, with neutral labels, with valve inside the cylinder, extreme low temperatures, special seals version 14404, with increased friction, with lockable cover tube

Push-out speed/damping:

-speed: fast/normal/slow

-damping: normal/increased/no end damping

connecting parts: find the right connecting in our offer

When considerable forces influence moving construction parts, reliable locking is vitally important. The piston rod of the lockable easylift® gas springs can be adjusted to any required position along the whole stroke by actuating the release pin.

Our lockable gas springs can be easily adapted to suit a wide variety of applications. All of our lockable gas springs share the same positive characteristics of low friction forces and high reliability as our standard gas springs.

Types:

Main type B: Spring locking

Main type K: Rigid locking in pull direction, push-in direction relatively rigid

Main type P: Rigid locking in push-in direction, pull-out direction relatively rigid

Main type KX: Rigid locking in push and pull direction

You can get this Gas Springs in following types:

Pull- in force: 100-4000N

Locking force in push and pull direction: max. 10.000N

Stroke: 10-350mm

Release travel: short release possible travel: < 1mm

Diameter piston rod/cylinder: 10/28 and 14/40

Speed/damping: normal, fast, slow

Connecting parts: the piston rod is available with the threads MF 10x1x18 for piston rod ø 10 or with, MF 14x1,5x20 for piston rod ø 14. Find the right connecting in our offer.

Bansbach easylift gas traction springs are available with your requested compression force ans specified features. All features, such as end damping and length, can be customized for your application needs. Our standard and lockable gas traction springs can help to slove many structural requirements in various technical fields.

corrosion- resisting material. We use medical grade 316L stainless steel for the production of our high quality stainless steel springs. These springs are not only resistant to water, but are commonly found in food, chemical, medical, and salt water applications. All gas springs in these high-quality product groups are made with a valve, with the exception of P-models and traction springs with damping.

In our offer there are also a large range of special Gas Springs. We have the click & go Gas Spring which have only one push on the

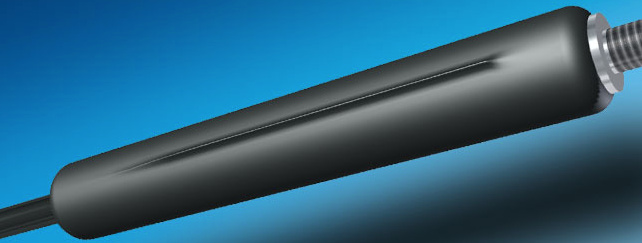

Also our XXL Gas Spring 30/70 have the power pack in jumbo format. The largest Bansbach gas spring is particularly interesting when large forces have to be moved or the stroke is to be correspondingly long.

The next special Gas Spring is our Aluminium Gas Spring. In many applications, the weight is decisive. This was the reason to develop the Bansbach gas spring completely of aluminium. This aluminium gas spring has the same characteristics as the other gas springs.

Another special is our click system which is integrated in your Gas Spring. With the new click system it is possible to lock the gas spring in its inserted final piston. This adjustment can be released without any further release systems. The piston rod has just to be pushed in slightly in order to move out then the complete stroke.

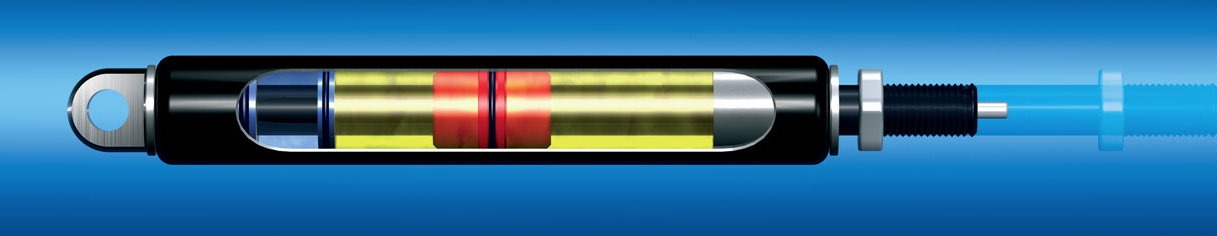

Also special is our damper who is adjustable in both directions.

Due to the groove, which is installed in the cylinder tube in this gas spring variant, the damping characteristic of the gas spring can be adapted very individually to the respective customer requirements.

- End damping ensured in every installation position (horizontal or with piston rod upwards)

- Controlled damping is possible regardless of position

- Individual damping characteristics over the complete stroke possible

In order to be able to design the groove, detailed information on the application and desired function of the gas spring is necessary.

Accesories

For precise and controlled force development, connecting parts that guarantee movement and force transfer in an ideal way are a necessity.

A brief overview about our connecting parts:

-Hinge eyes- Piston rod

-Hinge eyes- Cylinder

-Threads- Piston rod

-Threads- Cylinder

-Ball socket

-Bolts

-Elbow joints

-Clevises

-Clip bolt

-Hinge heads

-Ball joints

-Specials

-Brackets

There are different typs of release systems:

There are different typs of release systems: Release systems with lever:

-release system with lever

-variable release lever

Bowden wire release system:

-easytouch by wire

-flat grip

-bowdenwire (Linear)

-bowdenwire accessories

Hydraulic release system

-"easytouch" system

-classic hydraulic release

-hydraulic release sytem 5.3